Woodworking businesses rely heavily on the performance and precision of their equipment. Spindles are among the essential tools in their arsenal, which play a vital role in various woodworking processes. From cutting and shaping to routing and drilling, selecting the right spindles can significantly impact the efficiency and quality of your woodworking operations. This article guides you through choosing the ideal wood balusters for your woodworking business, ensuring optimal performance and productivity.

Understanding the Role of Spindles in Woodworking

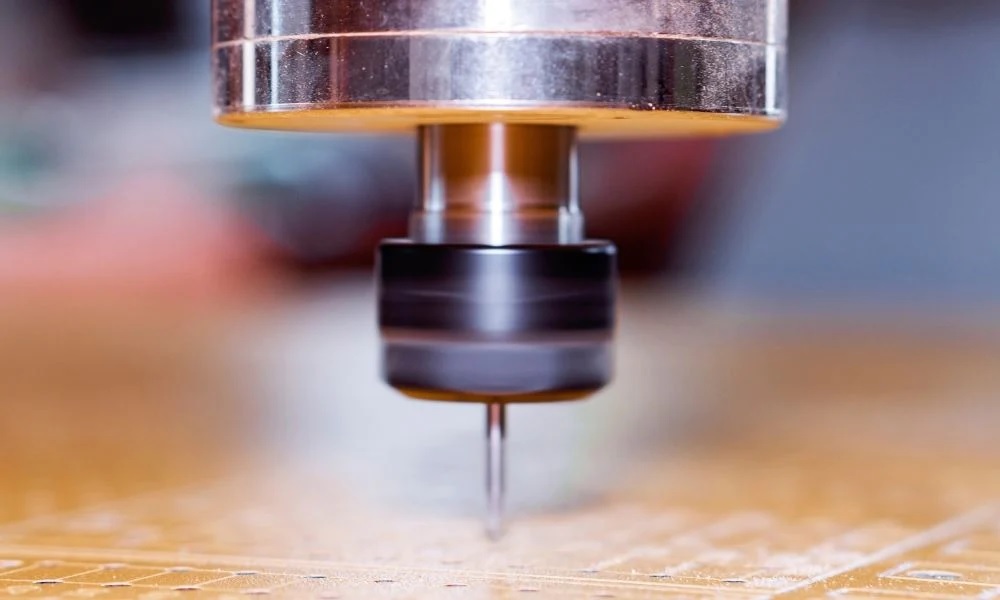

Spindles are rotating shafts that hold cutting tools or other attachments used in woodworking machinery. They provide the necessary rotational motion to perform tasks such as cutting, shaping, and drilling. The performance and capabilities of your spindles directly impact the precision and speed of your woodworking processes.

Assessing Your Woodworking Needs

Before diving into the various types of spindles available, it’s essential to evaluate your woodworking needs. Consider factors such as the type of woodworking projects you undertake, the materials you work with, and the level of precision required.

Types of Spindles for Woodworking

Woodworking spindles come in various types, each designed for specific applications. Common types include fixed spindles, motorized spindles, and CNC spindles. Fixed spindles provide stability and are suitable for basic cutting and shaping tasks. Motorized spindles offer variable speed control and increased power, making them ideal for more complex woodworking operations. CNC spindles are computer-controlled and provide precise movements, making them suitable for intricate and automated woodworking tasks.

Considerations for Selecting Spindles

Several factors should be considered when selecting spindles for your woodworking business:

- Power and Speed: Determine the power and speed requirements based on the materials and tasks you handle.

- Size and Compatibility: Ensure that the spindles are compatible with your woodworking machinery in terms of size and mounting options.

- Tool Holding Mechanism: Consider the tool holding mechanism, such as collets or chucks, to ensure compatibility with your cutting tools.

- Stability and Durability: Opt for spindles made from high-quality materials that provide stability and durability for long-lasting performance.

- Maintenance Requirements: Evaluate the maintenance needs of the spindles and choose ones that are easy to maintain without compromising performance.

Evaluating Spindle Manufacturers and Suppliers

Choosing a reputable and reliable spindle manufacturer or supplier is crucial to ensure the quality and performance of your spindles. Consider the following factors when evaluating potential manufacturers:

- Reputation and Experience: Look for manufacturers with a solid reputation and extensive experience in producing spindles for woodworking.

- Quality and Certification: Ensure that the manufacturer follows strict quality control measures and holds relevant certifications for their products.

- Customer Support and Service: Assess the level of customer support and after-sales service provided by the manufacturer.

- Pricing and Warranty: Compare pricing options and warranty coverage to make an informed decision.

Making the Right Choice

After considering all the factors and evaluating potential options, it’s time to make the right choice. Select the spindles that best meet your woodworking needs, ensuring they align with your requirements for power, speed, compatibility, stability, and maintenance.

Spindle Maintenance and Upkeep

It is crucial to maintain your spindles to ensure they perform optimally and last long. To achieve this, follow the manufacturer’s guidelines for cleaning, lubrication, and inspection regularly. To prevent any further complications, it’s important to frequently check for signs of wear or damage and address them promptly.

Conclusion

Choosing the right wood balusters for your woodworking business is a critical step toward enhancing productivity and achieving high-quality results. By understanding your woodworking needs, considering the various types of spindles available, evaluating manufacturers and suppliers, and prioritizing maintenance, you can ensure that your business operates smoothly and efficiently. Invest in high-quality spindles that align with your requirements, and you’ll see a significant improvement in the performance of your woodworking operations.

Comments