Your workdays are unpredictable. One minute everything’s running smoothly, and the next, your operations hit a wall. Maybe it’s a machine that stalls. Or worse, a sudden dip in air pressure that sends your entire workflow into chaos. Sound familiar? That’s exactly when rotary screw compressors step up. Quietly. Reliably. Powerfully.

These compressors aren’t just another line item on your equipment list. They’re your insurance policy against downtime. And if you’ve ever faced a missed deadline, an interrupted shift, or an unhappy client because of a mechanical failure, you already know the cost isn’t just financial. It’s personal. You carry the weight. You field the complaints. So you need tools you can count on when things go sideways. That’s where these compressors truly shine.

No Time to Waste? You Need a Machine That Keeps Its Cool

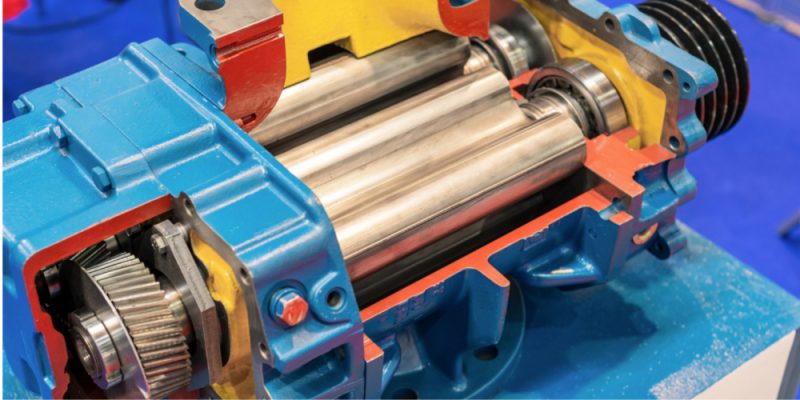

Rotary screw compressors are built for continuous duty. That means they don’t stop and start. They just keep going. They’re engineered for businesses like yours, where every second matters and pausing to reset a compressor simply isn’t an option. Whether you’re powering production lines or air tools, this type of compressor delivers a steady flow of compressed air without the hiccups you’ve probably dealt with before.

That reliability doesn’t just protect your output. It protects your peace of mind. You can breathe a little easier knowing you’re not going to get caught off guard. And in an industry that demands performance, consistency isn’t just helpful. It’s essential.

Racing the Clock? These Compressors Handle Pressure So You Don’t Have To

Your team’s working late to hit a shipping deadline. Orders are stacked, the line’s humming, and suddenly, one of your ageing compressors sputters. Pressure drops. Tools slow down. Your team stops. You’re left with the worst-case scenario—a halt in operations at the worst possible time.

Now imagine instead, you’ve got a rotary screw compressor system running the show. These machines don’t blink under pressure. They’re designed to handle intense workloads without overheating or losing power. So when everything’s on the line—customer satisfaction, delivery timelines, your reputation—they’ve got your back.

Tired of Watching the Meter Climb? Slash Your Energy Costs Without Sacrificing Output

Energy bills weighing you down? You’re not alone. In today’s economic climate, every unit of electricity counts. That’s where rotary screw compressors make a measurable difference. They’re built for energy efficiency, using internal mechanisms that minimise energy loss during the compression cycle.

And if you’re operating in Singapore, where businesses are increasingly expected to meet stringent energy standards, these compressors check the right boxes. They help you cut costs, stay compliant, and reduce your environmental footprint. All without sacrificing performance. Investing in an energy-efficient screw compressor system is more than smart. It’s strategic.

Everything’s Connected. Don’t Let One Failure Bring It All Down

When your air system falters, it doesn’t just slow down one tool. It triggers a chain reaction. Your processes halt. Your staff waits. Your revenue slips away. The worst part? You don’t always see it coming. That’s what makes rotary screw compressors such a smart investment. They’re built for continuous-duty performance and designed to run for hours or even days without fail.

You don’t have to babysit them or worry if they’ll make it through another shift. You can focus on what matters—delivering results, not managing downtime. You’ll quickly realise just how critical continuous-duty air compression equipment is to maintaining smooth operations.

Maintenance Without the Mayhem. Stay Ahead Without Losing Time

You don’t have time for complicated maintenance schedules. Your team’s already stretched, and any interruption—no matter how minor—feels like a disruption. That’s why rotary screw compressors are such a game changer.

Servicing is straightforward and often built into the unit’s design. With quick access to components and intuitive layouts, your technicians can get in, do what’s needed, and get out. No more tearing the system apart or losing hours on routine checks. Just smooth, manageable maintenance that keeps your system running strong.

In a Busy Workshop? Air Pressure Should Never Be a Guessing Game

In a fast-paced auto shop, timing is everything. When your team’s jumping from engine repairs to tyre changes, you can’t afford pressure drops or inconsistent airflow. That slows everyone down and frustrates your technicians.

A rotary screw compressor keeps things running with precision. No matter how many tools are operating at once, it maintains a steady, reliable flow of air. That means better efficiency, fewer delays, and faster service for your clients. You keep your team happy—and your customers coming back.

On the Edge of Nowhere? These Compressors Go Where You Do

Your job doesn’t stop at the edge of a city. Sometimes, your projects take you to offshore rigs, construction sites, or isolated operations where reliable power is hard to come by. That’s where rotary screw compressors prove their worth.

Built tough, these machines handle harsh conditions—heat, dust, vibration—without breaking a sweat. They don’t need constant supervision or backup units. They’re self-reliant, just like you. And models like oil-injected rotary screw compressors deliver the durability and performance required in rugged environments.

Workplace Safety Starts with Stability You Can Trust

Inconsistent airflow isn’t just annoying—it can be dangerous. Sputtering air tools lead to misfires, poor control, and avoidable accidents. But with a rotary screw compressor, you’re getting steady, dependable power that doesn’t drop off when you need it most.

That stability creates a safer environment for your team. And when your employees feel confident in their tools, they work faster, more accurately, and with fewer mistakes. Safety and performance don’t have to be trade-offs. You can have both.

Every Second Counts—Especially in Fast-Moving Manufacturing

In manufacturing, timing and precision are everything. And when you’re dealing with fast-moving processes like packaging perishables or bottling products, any interruption risks spoilage or product loss.

Rotary screw compressors keep your systems running smoothly—from conveyors and sealers to coolers and more. They’re the quiet force behind your daily output, giving you the consistency you need to meet tight schedules and high expectations. For many facilities, these systems are the heart of industrial compressed air solutions that support 24/7 operations.

In High-Tech Settings, You Can’t Afford Contamination

If you’re in electronics or medical production, you already know that one wrong particle can ruin an entire batch. That’s why you need compressed air systems that meet the highest cleanliness standards.

Rotary screw compressors protect your systems and your end products, helping you meet regulatory requirements without costly rework or recall headaches.

Your Warehouse Automation Is Only as Strong as Its Air Supply

Think your warehouse runs on electricity alone? Think again. Automated sorting systems, robotic arms, and high-speed conveyors all rely on compressed air. If that system falters, your whole operation can grind to a halt.

Rotary screw compressors are your quiet heroes in the background. They make sure everything keeps moving, even during high-volume periods like year-end rushes or promotional launches. You won’t notice them, but you’ll feel the difference when things run smoothly from start to finish.

Running Out of Space? These Compressors Make It Work

When space is tight, every square metre matters. Whether you’re in a small workshop or retrofitting an older facility, bulky equipment just won’t do. That’s why modern rotary screw compressors are designed with flexibility in mind.

Compact models give you the power you need without taking up valuable floor space. Wall-mounted or tucked neatly under existing systems, they adapt to your layout—not the other way around.

Hospitals Can’t Stop. Neither Can Their Air Systems

In healthcare, air supply is critical. From ventilators to sterilisation tools to cooling systems, compressed air supports the systems that patients and staff rely on every day. A single failure can impact lives.

Rotary screw compressors designed for medical use are quiet, consistent, and dependable. They’re built to meet strict operating standards without disrupting care. When your facility can’t afford to miss a beat, these machines keep things running behind the scenes.

Printing Delays Cost More Than Time. They Cost Trust

When you’re managing large-scale print runs, there’s no room for stalling. Whether it’s newspapers, packaging, or marketing materials, every job needs to be sharp, timely, and uninterrupted.

Rotary screw compressors power the tools that make that happen. They ensure a clean, constant air supply that supports high-quality output. You reduce blockages. You maintain precision. And you keep client trust intact, job after job.

Doing Right by the Planet (and Your Bottom Line)

It’s no secret—sustainability is no longer optional. If you’re under pressure to reduce energy use and emissions, rotary screw compressors with variable speed drives offer a clear path forward. They adjust output based on demand, so you only use what you need.

It’s a win-win that helps you future-proof your business while doing right by your community and customers. If you haven’t yet explored the benefits of a rotary screw air compressor Singapore businesses rely on, now’s the time.

When Trouble Hits, These Compressors Keep You Standing

Every operation hits rough patches. The question is, do your systems bend, or do they break? Rotary screw compressors help you weather the storm. They deliver performance when it’s needed most, keep your people moving, and give you one less thing to worry about when the pressure’s on.

If you’re considering screw air compressors, don’t settle for average. Go with a system that works as hard as you do. Explore your options and find the compressor that’s ready to step up when it matters most.

Comments